Textile-Based Pressure Sensors for Monitoring Prosthetic-Socket Interfaces

Transtibial amputees are often dissatisfied with their prosthetic devices. They are prone to experiencing discomfort while wearing their prosthetics due to excessive stress levels, humidity, and wetness which can lead to the development of additional medical conditions. An established hindrance in this field is a need for practical pressure sensors to monitor the environment within prosthetics, also known as the inner socket environment (ISE).

Pressure sensors are used to collect the data within the ISE that could be used to provide remote health care to amputees, including early detection of medical conditions or to design improved prosthetic devices. However, most sensors used for monitoring the ISE are rigid, bulky, and incur further discomfort to amputees.

Many of the disadvantages associated with current ISE monitoring approaches could be improved by utilizing textile-based sensors, which are relatively compliant, breathable, and simple to fabricate. They can be integrated within existing garments amputees commonly wear (i.e., socks and liner-liners). However, despite their many advantages, textile-based sensors have yet to be explored for ISE monitoring.

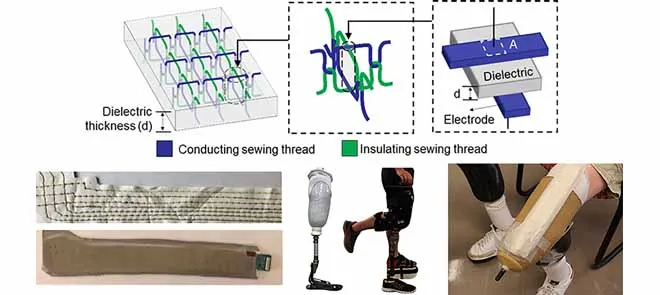

The work demonstrates a fully-textile seam-line sensor (SLS) approach in which fabric-based, pressure-sensing arrays are produced via a simple sewing process utilizing commercially available materials and machinery. It validated the SLS approach in a controlled lab testing environment. However, the focus was on a systematic approach to validating and integrating the sensors into a prosthetic environment.

First, the SLS was tested on an artificial limb to demonstrate its functionality in a simulated ISE. The artificial limb was secured onto a frame that allowed the limb to be tilted and secured at discrete angles. The SLS was placed within the artificial limb ISE, and then the limb was tilted to different angles to apply varying pressure levels to the SLS. The SLS provided qualitatively good results that followed similar trends to a commercially available system (the Pliance®), thus demonstrating their ability to sense in a simulated ISE.

Subsequently, the SLS was tested using a bent-knee adapter, a device worn by non-disabled individuals to simulate an ISE. Tests were completed with the bent-knee adapter to validate that the SLS could operate in a dynamic environment near the human body. During testing, the non-disabled individuals stood on a treadmill with a corresponding force plate which measured ground reaction force (GRF) during movement. They were asked to shift their weight on and off the sensor and walk during testing. Results indicated that the SLS provided sound results that correlated with the trends in GRF. Thus, the successful operation of the SLS in a simulated but relatively realistic ISE was demonstrated.

Finally, successful preliminary testing validated the SLS on a transtibial amputee subject. The amputee walked, shifting weights on and off the sensors, to complete weight-shifting and walking experiments on the split-belt treadmill. Again, the SLS provided qualitatively explainable results that could be correlated to the GRF.

The amputee indicated that the SLS caused no additional discomfort during use, thus validating the work and establishing that the SLS is a promising approach to fully-textile sensors for ISE monitoring.