Inertial Sensor Technology Trends

The technological advancement in inertial sensor technology challenged the dominance of electromechanical sensors in guidance, navigation, and control applications. The inertial sensor development has replaced many current systems that use ring laser gyroscopes or mechanical sensors. The new and emerging inertial sensor technologies are enabled by other sensors like interferometric fibreoptic gyros, micromechanical gyros and accelerometers, and micro-optical sensors and influenced by external additions like GPS, Doppler, star tracker, or seeker. The main driving force behind the advancement is the need for accuracy, small size, large-scale production and low production cost.

External aiding is necessary for accuracy since it aids in overcoming inertial sensor drift. GPS is a popular external aid choice for the inertial navigation system (INS) because of its cost efficiency and ubiquity. However still, the GPS signal may break due to deliberate jam, blockage or ionospheric delays. It's where the INS proves its relevance, and it takes over. Integrating INS with GPS has improved the ability to navigate various civilian and military applications, like controlling autonomous vehicles and guided artillery shells, to accomplish the mission accurately.

The current trends for inertial sensor technology developments include many upcoming enhancements in the military and commercial domains to cater to tactical-grade and navigation-grade applications. Focus is on cost-reducing too. These new technologies are Solid state inertial sensors, Fiber-Optic Gyro (FOGs), Micromechanical Gyros and Accelerometers.

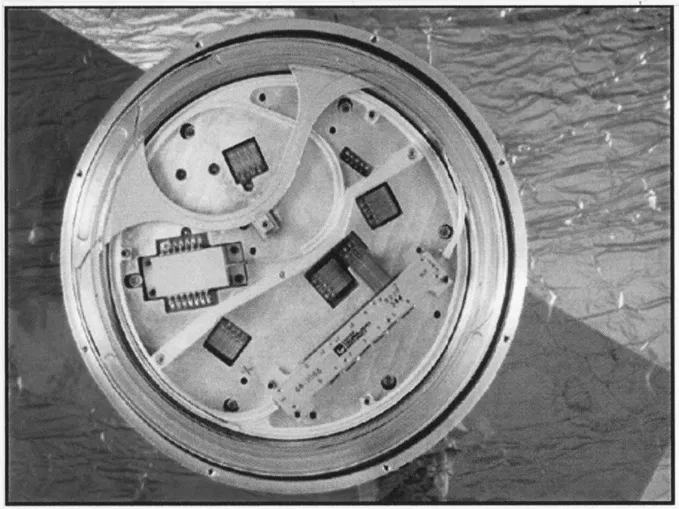

The earlier generation of electromechanical gyros include ring laser gyros (RLG), tactical interferometric fiber-optic gyros (IFOG), quartz resonant gyros, dynamically tuned gyros (DTG) etc. An FOG is configured using a fiber-optic sensing coil, integrated optics chip, a broadband light source and a photodetector that may be supplanted by quantum well technology. It allows the integration of complete system into a single substrate attached to the fibre-optic sensing coil, which reduces size and cost both. This makes FOG preferred over RLG in lower performance tactical and commercial applications.

Often fabricated out of a single piece of quartz or silicon, MEMS-gyros are usually designed as an electronically driven resonator where thousands of devices can be embedded on a single 5-in silicon wafer. Similarly, a MEMS-accelerometer is a monolithic silicon structure. Its compact size and the strength of silicon make it ideal for high acceleration applications, like in artillery guns, automotive airbags, and skid and ride control in automobiles.

The emerging technologies and future in the inertial sensor are now shifting interest towards Optical MEMS, also known as micro-optics or micro-optical electromechanical systems (MOEMS), where lies the room for development. The Optical MEMS sensors have the edge over MEMS sensors since they are purely be solid-state devices. The solid-state inertial sensors have significant cost, size, and weight advantages, resulting in their increased applications.

With increasing understanding of parameters like geometry, size, electronics, and packaging on performance and reliability is going to rule the next generation of inertial sensors. MEMS devices with capacitive readouts will soon be replaced by optical readouts. Communications industry is witnessing the advancement of resonant microspheres. With its super-high-performance IFOG will become the dominant gyro by replacing electrostatically-suspended gyros (ESGs). Silicon and quartz resonators are also quite visible on the horizon.