High-Sensitivity CQDs-Modified ZnO Nanowire Gas Sensor Fabricated on 3-D Substrate for Acetone Detection

Detecting acetone gas with high sensitivity and selectivity is critical due to its widespread industrial use and the health risks of prolonged exposure. Conventional zinc oxide (ZnO) nanowire gas sensors face challenges such as limited sensitivity, high operating temperatures (~300°C), and poor selectivity, which limit their practical applications.

This study addresses these limitations by developing a novel gas sensor that combines carbon quantum dots (CQDs) modified ZnO nanowires on a three-dimensional silicon micropillar substrate.

The 3-D micropillar structure, fabricated using Bosch deep reactive ion etching (DRIE), greatly increases surface area, promoting stronger gas adsorption and enhanced interaction with the sensing material compared to planar substrates. Four 3-D substrates with varying pillar diameters and heights were tested.

ZnO nanowires were grown uniformly on both 3-D and planar substrates using a two-step hydrothermal method with aluminum doping, which increases electron concentration and enhances conductivity.

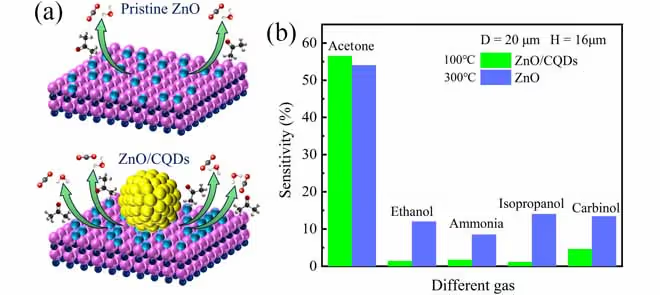

CQDs, produced via environmentally friendly methods from corn stalks, were uniformly spin-coated onto the ZnO nanowires, forming a heterojunction with abundant surface functional groups that promote selective acetone adsorption. Transmission electron microscopy and X-ray diffraction confirmed well-aligned hexagonal ZnO nanowires densely decorated with CQDs.

X-ray photoelectron spectroscopy revealed the formation of C–O–Zn bonding and increased oxygen vacancy concentrations on the ZnO/CQDs sensor surfaces. These oxygen vacancies act as active sites, enhancing gas adsorption and reaction rates, critical to sensing performance.

The p-n heterojunction formed between P-type CQDs and N-type ZnO nanowires creates depletion zones and modulates the band structure. This results in a higher baseline resistance and a stronger response to acetone exposure.

Gas sensing tests for acetone showed that sensors on the 3-D substrate performed much better than planar sensors, achieving up to 85% higher sensitivity at 300°C.

Remarkably, the ZnO/CQDs sensor on the 3-D substrate reached about 50% sensitivity at a much lower operating temperature of 100°C, compared to pristine ZnO, which requires 300°C. This large reduction in temperature is due to the CQDs’ abundant surface oxygen-containing groups, which enable low-energy adsorption and reaction of acetone molecules.

Selectivity tests demonstrated that the CQDs-decorated sensor strongly favors acetone detection over other gases, including ethanol, ammonia, isopropanol, and methanol. This enhanced selectivity arises from specific chemical interactions between acetone’s carbonyl groups and the hydroxyl/carbonyl groups on the CQDs surface, improving adsorption affinity.

The sensing mechanism involves oxygen adsorption on ZnO, forming ionized oxygen species that capture electrons, increasing baseline resistance. When exposed to reducing acetone, these reactions release electrons back into ZnO, lowering resistance. The CQDs-ZnO p-n heterojunction amplifies these resistance changes, further enhancing sensitivity.

Combining a 3-D micropillar substrate with CQDs modification effectively overcomes major limitations in acetone sensing. The sensor achieves higher sensitivity, lower operating temperature, and improved selectivity, offering a scalable approach for next-generation metal-oxide-semiconductor gas sensors. Its high sensitivity, low operating temperature, and excellent selectivity make it suitable for scalable, energy-efficient, and reliable gas-sensing solutions for industrial, commercial, and environmental monitoring.