Hardware Technology of Vision-Based Tactile Sensor: A Review

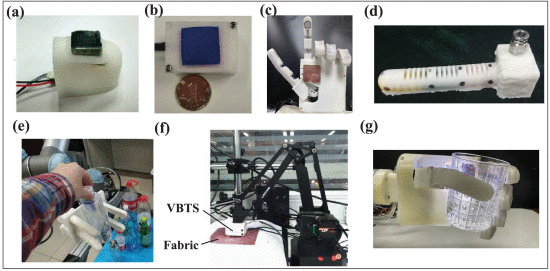

Tactile sensors have significantly improved the versatility and adaptability of robots, enabling them to perform various tasks with precision. The commonly used tactile sensors include capacitive, piezoresistive, fiber, proximity, and vision-based sensors. There has been a rapid development of vision-based tactile sensors (VBTSs) in recent years. It had the potential to provide robots with high-performance perception.

The paper presents a detailed study of contemporary hardware technologies of VBTSs. The article analyzes each module for hardware types, materials, preparation processes, performance, and integration technology.

A VBTS is a unique optical sensor with a contact module, illumination and camera module, and information processing module. The contact module is the core, containing the contact body, reflective, protective, and marker layers. VBTSs capture tactile information by recording and processing images through a reflective layer, which captures brightness differences from emitted light, forming tactile images.

Silicone is a commonly used material for contact body fabrication. The main process includes proportioning silicone, pouring the mold, vacuuming, curing, and demolding. The camera observes contact features through a transparent contact body. Its hardness determines tactile perception and sensitivity.

The marker layer reflects the deformation state, indirectly deriving the contact force. The marker density, size, and shape are related to the precision and resolution of force measurement. A single-layer marker array has limitations in normal force coupling. The double-layer marker array increases spatial contrast, which enhances normal force representation.

The reflective layer is a thin and flat coating to transfer tactile details. It can be classified into semi-specular and matte coatings. The spraying process can fabricate a high-quality coating with a more uniform surface than the painting coating. Meanwhile, it has a lower cost than the sputtering coating.

The thinner reflective layer enhances sensitivity to microgeometry deformation, but its wear resistance is lowered. The protective layer can protect the reflective layer from direct contact with the object. It needs to be as thin as possible to reduce the impact of sensitivity. Wear resistance improvement of the reflective layer is the most effective approach.

With the development of miniaturization, the sensor's radial size is limited. Therefore, the vertical illumination is replaced with the side illumination, where LEDs surround acrylic or contact body sides. When the total internal reflection condition is satisfied, the light is uniformly distributed on the contact surface. Acrylic is made into different shapes of lenses to act as a medium for light transmission.

The micro camera plays an increasingly important role in VBTS miniaturization. It only retains imaging sensors and circuit boards while maintaining high-quality imaging. Different types of lenses provide camera function expansion, such as imaging quality enhancement, imaging distance adjustment, and visual field expansion.

The process flow of VBTSs is established via a coding method. The paper discusses some feasible solutions for the current challenges and problems with hardware technologies. Cutting-edge interdisciplinary hardware technologies are expected to promote the development of next-generation VBTSs. The paper provides a valuable reference for the research community in future improvements to the hardware performance of VBTSs.