Flexible Strain and Temperature Sensing NFC Tag for Smart Food Packaging Applications

Microbial contamination is associated with the oxidation of the food content that releases many gases resulting in blown package spoilage (BPS) in vacuum-packaged food. Also, temperature alteration inside the pack can induce microbial growth in the food. So, the researchers considered these two critical parameters to develop sensor-based applications for the quality assurance of packaged food.

Among all the alternatives, flexible strain sensors are the best to detect small deformations in a food package. PEDOT: PSS is chosen as a sensing material for both the temperature and strain sensors due to its stable electrical properties in higher ranges in temperature and mechanical deformation.

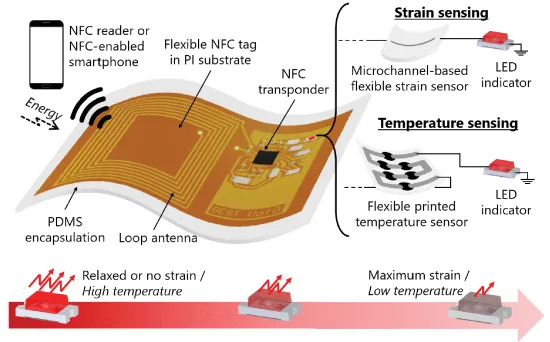

For the strain sensor, a microchannel is fabricated inside PDMS (polydimethylsiloxane) substrate, and PEDOT: PSS is injected into it. After drying, when there is an applied strain, its resistance changes according to its dimensions. The sensor has an average gauge factor of ~13000 and <9% hysteresis. For the temperature sensor, the silver electrodes are printed by a stencil printing method, and PEDOT: PSS is drop-casted on 6 gaps in series. The sensor response was linear and had a negligible hysteresis of < 3%. The strain is measured by customized strain measurement equipment, and the temperature was measured precisely by IR (Infrared) thermometer for the calibration.

The widespread availability of NFC-enabled smartphones makes the NFC reader easily accessible. So, an NFC antenna is designed to harvest smartphone energy to power the sensor patch. The RFID chip used for the NFC antenna is a 13.56 MHz transponder from Texas Instruments (model RF430FRL154H). It comes with a 16-bit low-power microcontroller (MSP430). The designed NFC antenna has a planar internal inductance of 1.84 mH (for smaller sizes), and the RFID chip has an internal capacitance of 35 pF. An external capacitance of 40 pF to achieve resonance frequency at 13.56 MHz. With this design, the NFC tag can harvest energy from the electromagnetic (EM) field induced by an external NFC reader and provide up to a current level of 500 mA with 2 V regulated voltage, i.e., sufficient for an LED to glow.

The flexible PCB (printed circuit board) is fabricated on flexible polyimide (PI) by ultraviolet etching. The LEDs are connected in series with the sensors; hence, their intensities depend on the sensor's resistance. To characterize the LED, a generic lux-meter mobile application is used. With higher sensor resistance, i.e., higher strain in the strain sensor and lower temperature in the temperature sensor, the LED glows dimmer. PDMS layers encapsulate the whole sensor patch to protect it from environmental factors. The sensor is tested on the fresh meat package and the same when it gets spoiled a few days later. With the smartphone NFC reader, LED glows if the food condition is good and is turned off in case of spoilage.

The simple design of the sensor patch does not need any analog-to-digital converter module or any external power source. Thus, this design of the NFC chip can be incorporated into any sensor front-end interface. In the future, this type of system can enable AI (artificial intelligence) to automatically decide the next course of action in factories and supermarkets.