Electronic Waste Reduction through Devices and Printed Circuit Boards designed for Circularity

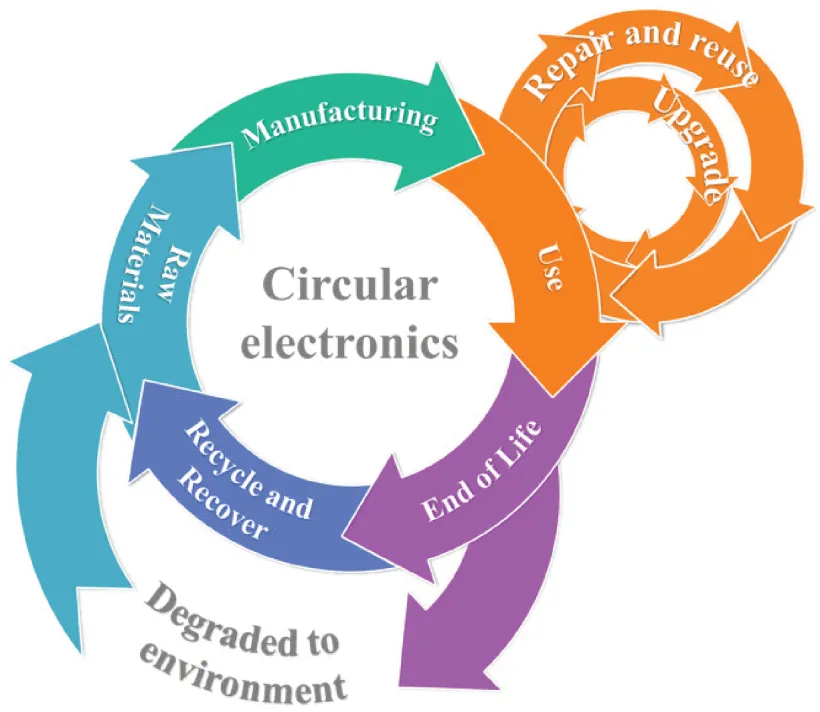

The advances in electronics over the last more than 50 years have revolutionized all traditional socio-economic sectors, e.g., health, agriculture, transportation, manufacturing, retail etc. Electronics form the backbone for advances in several emerging areas such as automation, smart cities, connected everything, Industry 4.0, robotics, virtual/augmented reality, 5G/6G communication, etc. Yet, as revolutionary as electronics have been, the production and integration process it follows is inherently and unavoidably wasteful in its current form. The current ‘take-make-waste’ model of production and consumption is unsustainable, and a reboot is needed toward circular sustainable electronics.

A substantial part of WEEE (~42%) comprises Waste Printed Circuit Boards (WPCB), which typically use a substrate such as FR4 (Flame Retardant 4) - a composite material made of woven fiberglass cloth with an epoxy resin binder. Such materials constitute a considerable part (~70%) of WPCB and pose a major environmental challenge as they contain toxic substances such as brominated flame retardants (BFR) and non-metallic materials (glass fibre, epoxy resin). The wastage of highly purified metals (copper, silver, nickel, etc.), which have limited reserves, also raises the concern related to sustainability. There are advantages in transitioning away from such materials from a legal, environmental and economic perspective. The highly desirable aim is to reuse and achieve a 100% closed loop of materials, heat, and energy. New methods should be explored with circular electronics, resource efficiency, and sustainable design principles at the core.

To address the issues of e-waste, the governments and policymakers are now actively encouraging repair and extended life for electronics, thereby delaying the consigned to landfills. The European Union’s (EU) WEEE Directive is one such example. Sadly, these are reactive policies. It is worthwhile to promote a proactive approach involving switching to developing Electrical and Electronic Equipment (EEE) that uses sustainable materials and resource-efficient manufacturing.

Considering the circular-economy strategies for electronics, state-of-the-art should focus on new and emerging materials to reduce the impact of WPCBs, which make a significant part of WEEE. The materials currently used in Information and communications technology (ICT) hardware show a heavy dent in environmental impact. A ‘periodic table of sustainable electronics’ is reported for the first time to assess the environmental and human toxicity impact of different elements relative to their abundance within WPCBs. The motivation for this discussion is to identify which eco-friendly materials and new technologies will be needed to improve the sustainability of the industry. It is followed by a comprehensive analysis of WEEE processing and the projection of expected future trends.

The challenges, potential solutions and new opportunities that may arise from greater use of sustainable materials and resource-efficient manufacturing are elaborated. We hope it will stimulate the discussion about revising policies from the current focus on waste management to waste reduction and zero waste. It is believed that the researchers and practitioners from academia and industry will benefit from the in-depth discussion in this article.