Design and Implementation of a System to Control Bioreceptor Layer Formation on Au Electrodes

Electrochemical biosensors, designed to detect specific analytes such as toxins or pathogens, generally comprise a bioreceptor, an electrochemical transducer, and a signal-processing system. A critical fabrication step is modifying electrodes with biological molecules that bind the target analyte, a process strongly influenced by both the bioreceptor solution and electrode surface properties. Ensuring the stability of this functional layer is challenging due to its sensitivity to parameters like temperature, humidity, and pH. Proper electrode surface preparation is therefore essential for reliable bioreceptor attachment.

The study proposes a system integrating online wetting angle measurements with electrochemical impedance spectroscopy (EIS) to monitor the quality of gold electrodes during the early stages of biosensor production. Wetting angle analysis evaluates the surface cleanliness and wettability of the electrode, ensuring proper conditions for bioreceptor attachment, while EIS provides electrochemical information on layer uniformity and binding efficiency. The study aimed to develop a quality control system that integrates seamlessly into existing production processes without adding complexity.

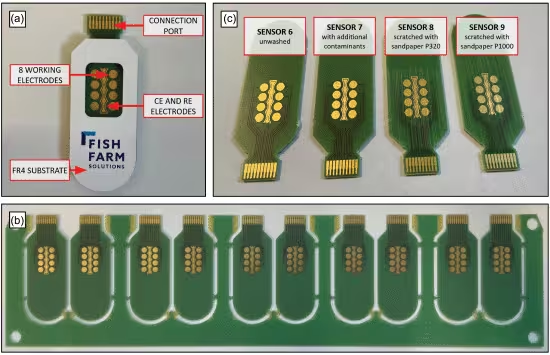

The researchers first optimized the biosensor's design and structure to ensure the system could be applied effectively. The sensors were built on a glass-fiber-reinforced epoxy laminate substrate and included eight gold (Au) electrodes created through electrochemical deposition. Each sensing electrode was a 2.7 mm circular disc, paired with a reference (RE) and a counter (CE) electrode to ensure accurate measurements.

To monitor and improve production quality, the team developed two key systems: a Single Substrate Control System and an in-situ production setup.

The Single Substrate Control System was designed to measure the wetting angle of biosensor electrodes during testing precisely. Unlike traditional goniometers, which are expensive and rely on metal syringes, this low-cost, custom-built optical tensiometer was made specifically for biosensor substrates. An automated pipette dispensed droplets rather than a syringe to better mimic production conditions, and droplet images were analyzed to accurately calculate wetting angles. This setup allowed near-industrial testing while maintaining flexibility and precision.

The in situ production setup is a robot-assisted, camera-based, impedance-enabled quality control system that monitors the surface and electrochemical properties of gold electrodes during processing. It captures images and measures wetting angles without interrupting production. Key tasks such as liquid handling, droplet application, image capture, and electrode inspection are fully automated.

During laboratory tests, drops of deionized (DI) water with a conductivity of 0.05 μS/cm and bioreceptor solutions were applied to nine electrodes- five cleaned and four uncleaned for comparison. Cleaned electrodes showed lower wetting angles (67° with DI water, 61° with bioreceptor solution, and 59.9° after layer formation), indicating improved hydrophilicity and stable bioreceptor bonding. The uncleaned electrodes showed higher angles (75–79°), confirming weaker surface wetting. This 8° difference between cleaned and uncleaned surfaces highlights the importance of surface treatment for sensor reliability.

Overall, the integrated real-time quality control system enhances biosensor accuracy, stability, and scalability. It enables early defect detection, ensures electrode consistency, reduces waste and costs, and supports automated manufacturing, providing a robust approach for high-quality biosensor production.