Scorpion-Inspired, Hydrophobic, Highly Sensitive, and Paper-Based Magnetoelastic Biosensor for C-Reactive Protein Detection

C-reactive protein (CRP), typically found at low levels in healthy individuals, is a critical biomarker for acute infection and inflammation. Elevated CRP levels indicate tissue damage, requiring precise detection for accurate diagnosis and prognosis. Existing detection methods, including immunochromatographic assays, ELISA, and chemiluminescent assays, suffer from sensitivity and cost limitations.

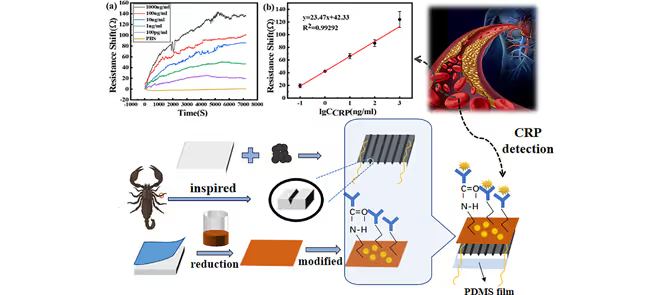

This study introduces a novel paper-based magnetoelastic (ME) biosensor for CRP detection. This biosensor, characterized by hydrophobic and eco-friendly properties, incorporates V-shaped grooves inspired by scorpion anatomy to enhance sensitivity.

The substrate consists of photo paper (P-paper) functionalized with cobalt ferrite (CoFe2O4) and multi-walled carbon nanotubes. A polydimethylsiloxane (PDMS) sealing layer is applied to maintain hydrophobicity.

The biomodification site for CRP antibody binding utilizes gold nanoparticles (AuNPs) combined with PDMS. This setup facilitates the conversion of specific antigen-antibody interactions into detectable signals.

The ME biosensor achieves a limit of detection (LOD) of 100 pg/mL and operates within a linear range from 100 pg/mL to 1000 ng/mL. This advancement significantly enhances CRP detection capabilities, providing rapid responses and high sensitivity for medical diagnostics and environmental monitoring.

Using paper as a substrate provides advantages, including accessibility, cost-effectiveness, biodegradability, and ease of processing. However, challenges persist due to water-induced expansion and degradation, underscoring the necessity for enhanced waterproofing and sensitivity.

The V-shaped grooves of the biosensor enhance conductivity by emulating scorpion sensory mechanisms. When subjected to compressive stress, these grooves deform, which increases both the contact area and conductivity. Conversely, conductive pathways are reduced under tensile stress, leading to increased resistance. This innovative design effectively facilitates the detection of subtle biological signals.

The fabrication process involves preparing the MWCNTs/CoFe2O4/paper composite by mixing CoFe2O4 powder with deionized water, sonicating, soaking in CoFe2O4 nanofluid, and drying. The AuNPs/PDMS composite is created by mixing PDMS, defoaming, and spin-coating it onto the glass before treating it with a gold nanoparticle solution. The anti-CRP modification process includes immersing the AuNPs/PDMS films in a cysteamine solution to activate and immobilize the antibody.

Characterization of CoFe2O4 powder using transmission electron microscopy and vibrating sample magnetometry reveals high surface energy and a saturation magnetic induction strength of 90 emu/g. The paper composite is analyzed using scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS), confirming a uniform distribution of CoFe2O4 nanoparticles and MWCNTs across the substrate.

Post-immobilization, SEM reveals surface changes, and EDS confirms carbon, nitrogen, and oxygen presence. Mechanical analysis indicates a compression modulus of 11.449 MPa, reflecting the biosensor's resilience. Compressive stress reduces resistance due to interconnected MWCNTs, while tensile stress increases resistance by disrupting these connections. Antigen concentrations of 100 pg/mL to 1000 ng/mL correlate with CRP detection, confirming a limit of detection (LOD) of 100 pg/mL.

Stability tests reveal consistent resistance shifts, yielding a relative standard deviation of 9.56%. This study demonstrates a sensitive and hydrophobic ME biosensor for CRP detection, utilizing AuNP/PDMS-Paper-PDMS composite structures. Its low-cost fabrication, specificity, and stability indicate its potential for medical diagnostics and monitoring inflammatory conditions.