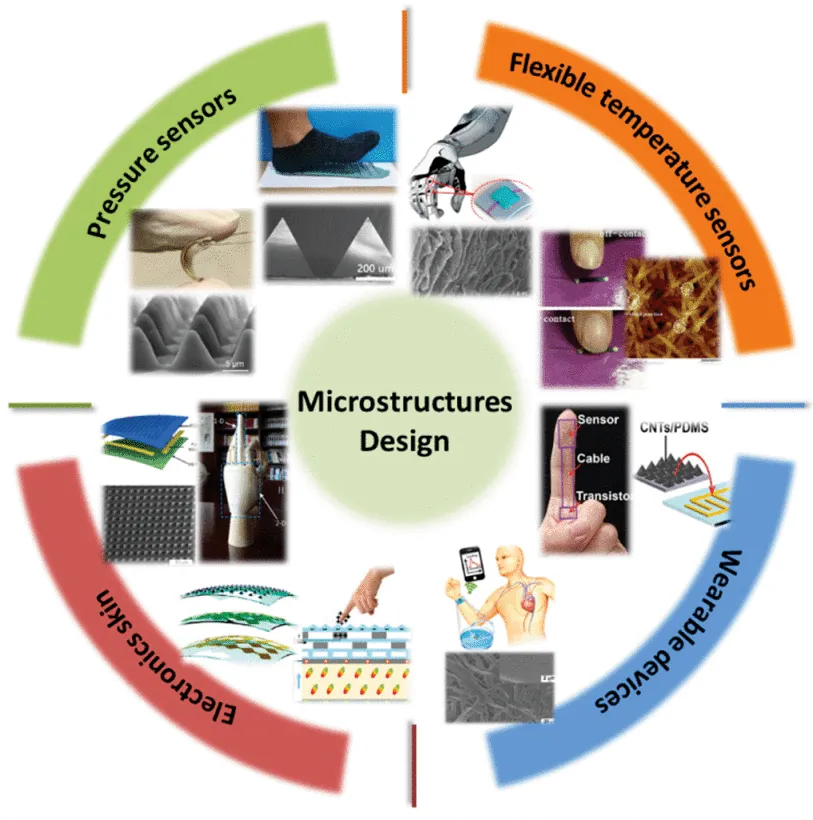

Recent Applications of Different Microstructure Designs in High Performance Tactile Sensors: A Review

A wide range of tactile information, such as temperature, texture, pressure, and vibration, can be sensed by humans through their skin. The aim of recent research in tactile sensors has been to match the sensitivity of human skin. High sensitivity and spatial resolution are two key factors that help obtain sufficient contact information. These factors determine the accuracy of the simulated tactile mechanism of humans.

The limitations of Young’s modulus and the elasticity of polymer materials restrict the performance of the flexible conventional tactile sensor, making it difficult to mimic human skin. However, microstructure, the three-dimensional spatial geometries of single or composite materials on a micron scale, is integrated into sensitive functional materials and is crucial in maximizing the sensitivity and resolution of tactile sensors.

The microstructures can be broadly divided into four categories. The first is a microstructure with a standard arrayed layout suitable for batch production, which can take shapes like a pyramid or a cylinder. The advantage of the pyramid geometry is that its tip can be deformed appropriately across a small pressure span. It allows for producing capacitive and piezoresistive tactile sensors that are highly sensitive to changes in capacitance and resistance. The cylinder’s vertical nature enables the utilization of shear strain to detect tangential mechanical variables.

Organisms inspire the second type of microstructure. One such design is an e-skin system inspired by finger skin. This design adopts a double spiral structure as electrodes create an alternating voltage when it slides on rough surfaces. Another design relies on the ability of crack-shaped receptors and cilia on insect limbs to acquire tactile information. Some novel ideas for microstructure design are derived from the microscopic plant constructions on rose petals and lotus leaves.

The next is based on materials. The geometric characteristic of the materials can be utilized to build ultra-sensitive and ultra-thin microstructures. One microstructure is the micro-nano fibre network, where the nanowires are aggregated regularly or repeated randomly to form sequential or complex 3-D networks acting as planar or deformable conductive networks. It helps in transferring energy during the process of sensing. One other microstructure is the laminated distribution structure. It is formed by vertically accumulating flake-like materials to obtain laminated microstructures. The property is used to build a sensor with high sensitivity.

The final category is microstructures with an irregular distribution, which leads to better Young's modulus and elasticity to obtain high-performance tactile sensors. The geometric feature is of spongy, porous structures, with different size cavities forming multiple interconnections between holes in a dense and disorderly matrix. It is used to make a wide array of tactile sensors. Paper-based microstructure takes advantage of the paper's tailor-ability to build flexible tactile sensors, the shape of which can be modified to suit the users.

With the expanding applications of tactile sensors and information, the performance of these tactile sensors faces many challenges. An exciting revelation was that the intelligent combination of various microstructures might lead to a better balance of sensitivity, linearity, and hysteresis of tactile sensors and help realize the bionic performance of devices. However, there is scope for improvement and many challenges to overcome in the design and fabrication of microstructure.