Online Learning for Active Odor Sensing Based on a QCM Gas Sensor Array and an Odor Blender

The paper discusses enhancements to active odor sensing, an iterative process where an electronic nose and an odor blending system collaborate to replicate a target smell. The core innovation proposed in this research is the online adaptive calibration of the electronic nose sensors' models during active odor sensing. This approach makes the system more resilient to variations in the gas sensor characteristics during the measurement.

The system consists of a gas sensor array and an odor blender. The gas sensor array employs four Quartz Crystal Microbalances (QCMs) coated with different sensing materials that absorb the odor molecules. Simply put, the mass of these molecules alters the sensors' natural oscillation frequency, and this frequency shift is interpreted as the sensor response. The odor blender is a high-precision device capable of mixing various odor ingredients at controlled concentrations. The blended odors are then delivered to the electronic nose.

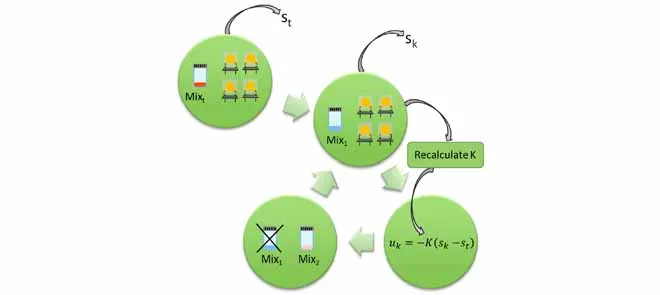

The active sensing process involves measuring a target odor with the sensor array and then employing the odor blender to create a similar odor mixture. The sensor array then measures that tentative replicated odor. The difference in sensor responses to the original and replicated odors is used to adjust the odor blender settings. This cycle is repeated until the sensor responses closely match. A Multi-Input Multi-Output (MIMO) control loop, integrated into the system through MATLAB programming, manages this process. The optimal closed control loop is designed based on classical theory, and initial calibration of the sensor responses to the odors of the blending ingredients is essential.

However, gas sensors' sensitivity to odors is not stable over time due to factors like drift, humidity changes, and temperature variations, and frequent manual recalibration for optimal performance is required. To address this, an adaptive control based on recursive least squares estimation of the sensor models is incorporated into the algorithm. The evolving relationship between odors and sensor responses is continuously modeled during active sensing without stopping the active sensing procedure. The recalibrated sensor response model is then used to redesign the optimal controller at every step.

The study evaluates the system's robustness against sensor drift and humidity variations. Significant sensor drift over weeks and humidity changes up to 15%, both realistic scenarios, are introduced, including scenarios where humidity levels gradually increase. It is observed that the accuracy of the system without adaptive control diminishes under these altered conditions. However, the adaptive control achieves 18-25% lower errors in quantifying odor concentrations. The time required for the system to stabilize (convergence time) was also analyzed and found to be comparably efficient between the basic and online learning algorithms.

This research marks a significant advancement in odor-sensing technology. By integrating adaptive online learning into an active odor-sensing system, the researchers have enhanced accuracy and robustness against environmental changes. This technology could significantly improve electronic noses and odor reproduction systems, overcoming inherent limitations of gas sensors, with potential applications ranging from environmental monitoring to the food and fragrance industries.