Nonanal Sensor Fabrication Using Aldol Condensation Reaction Inside Alkali-Resistant Porous Glass

With the progressive aging of the global population, illness prevention, rather than disease treatment, has become increasingly important. Human-exhaled breath contains various volatile organic components (VOCs). VOC analysis allows for early-stage disease detection. A simple gas sensor that can accurately detect trace amounts of gas is required to enable early detection.

Early-stage lung cancer is difficult to detect and has a high mortality rate. In recent years, a diagnosis method has been reported, which has been used to analyze the concentration of nonanal gas in exhaled breath accurately.

Porous glass has open nanopores and high visible-light transparency. Due to these advantages, porous glass was selected as the reaction field between the gas detection agents and target gas, making this sensor a porous glass gas sensor. The target gas adhered to the water layer formed on the inner walls of the pores upon entering the pores. It then reacts with the detection agents to generate a reaction product that absorbs light of a wavelength different from that absorbed by the agent, enabling target gas detection.

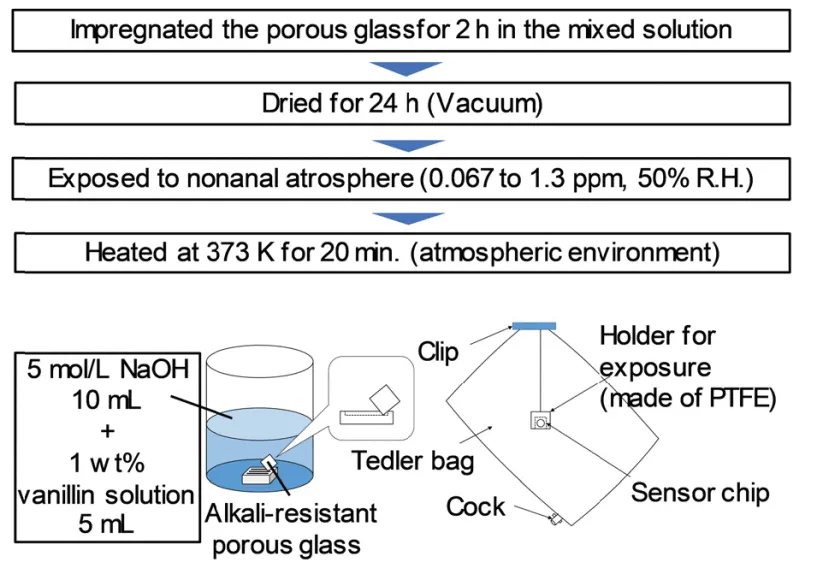

The researchers developed a novel nonanal sensor chip using alkali-resistant porous glass, in which an aldol condensation reaction between vanillin and nonanal was employed for gas detection. When vanillin and nonanal undergo aldol condensation, they cause changes in the adsorption spectrum. This reaction requires an alkali catalyst. The results of the solution system test showed that the reaction product had an absorption peak in the wavelength range of 400–450 nm, wherein vanillin and nonanal do not absorb.

A nonanal sensor chip was fabricated by immersing vanillin and NaOH as alkali catalysts into the alkali-resistant porous glass. The nonanal gas concentration and absorption change of the sensor chip had a linear relationship in the 60–1300 ppb range, indicating that the sensor chip can be used for quantitative nonanal concentration evaluation. The changes in absorption were measured at 470 nm. Therefore, this biological marker gas sensor is effective for the early diagnosis of diseases.

The developed alkali-resistant porous glass showed a lower weight loss (20% of conventional porous glass). The superior alkali resistance was attributed to the use of ZrO2. Sodium silicate hydrate, known to polymerize with increasing density, is the product of diluting glass with NaOH aqueous solution, reducing the amount of SiO2 eluted by alkali, leading to the reduction of obstructive gel-like products in the pores. The sensitivity of the sensor chip produced using alkali-resistant porous glass was higher than that of the sensor fabricated using conventional porous glass. The gas detection agent was assumed to be homogeneously supported inside the pores.

Biomarker gases include different materials and reflect the corresponding bioinformation. Gas sensors require high portability, sensitivity, and selectivity to utilize the valuable information provided by biomarker gases. The study has the potential to satisfy these requirements. Specifically, aldol condensation in alkali-resistant porous glass was achieved in a basic-pH environment, unlike in conventional porous glass. This resulted in higher sensitivity to nonanal gas, which is a significant biomarker gas candidate for lung cancer detection.