Liquid Crystal Microlens Arrays Based on Aluminum-Doped Zinc Oxide Oriented Microstructure Facilitate Light Field Image Resolution Enhancement

Traditional optical imaging techniques have several limitations and challenges. They are generally confined to two-dimensional projection recording, which means they cannot capture the complete three-dimensional characteristics of a scene. The depth of field is also severely restricted, causing the out-of-focus areas to appear blurry. Additionally, these techniques lack sufficient light-gathering capacity, leading to poor image quality in low-light conditions.

Light-field imaging technology can provide comprehensive scene information. However, it faces constraints due to the characteristics of specific Charge-Coupled Device (CCD) sensors, which limit its overall performance. Liquid crystal microlens arrays (LC-MLA) seem to provide robust solutions to these long-standing challenges. However, the unstable and disordered alignment of liquid crystal molecules in traditional LC-MLA significantly reduces their effectiveness, thus hindering their widespread application.

This paper presents novel aluminum-doped zinc oxide (AZO) microstructures designed for aligning liquid crystal molecules in micro-lens arrays (LC-MLA), significantly improving their integration into light-field imaging devices. The AZO microstructures leverage a synergistic effect of Berreman’s groove theory and surface tension to induce horizontal liquid crystal alignment along substrate planes, facilitated by their periodic groove architecture. Aluminum doping causes changes in the lattice structure, generating oxygen vacancies that increase surface polarity and chemisorption capacity. As a result, this enhances the surface energy of the alignment layer, reduces liquid crystal contact angles, and stabilizes horizontal alignment, thus significantly improving the performance and reliability of LC-MLA.

The manufacturing process begins with photolithography and wet etching to construct the microstructures of the alignment layer and then precisely depositing an AZO film via pulsed direct current (DC) sputtering. Subsequently, using the AZO as the bottom alignment layer for the liquid crystals, it is assembled with components like the top-friction polyimide (PI) film and the microporous patterned indium tin oxide (ITO) electrode. This assembly leads to the forming of the aluminum-doped zinc oxide liquid crystal microlens array (AZO LC-MLA).

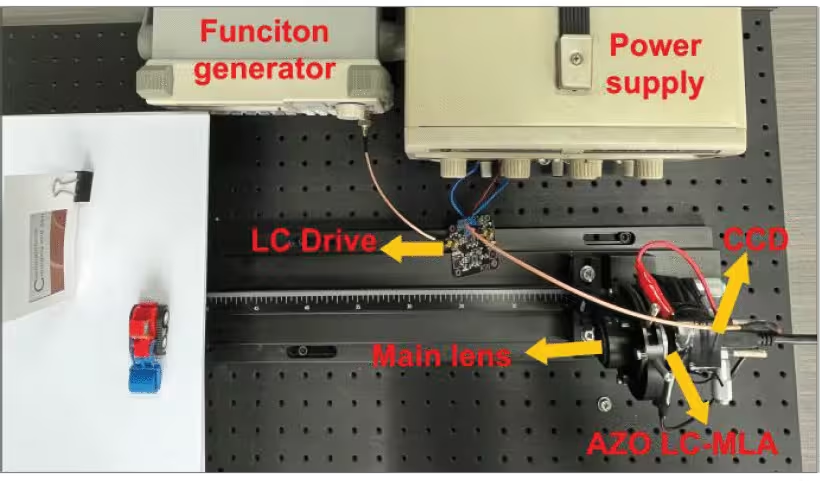

The AZO LC-MLA-based light-field camera imaging system demonstrates exceptional performance. When the AZO alignment layer efficiently aligns the liquid crystal molecules, the system effectively modulates and focuses the light field by utilizing the electrically controlled focusing and birefringence properties of the liquid crystal. The high transmittance, superior alignment performance, and electrical conductivity of the AZO alignment layer boost the light transmission efficiency, accelerate the response speed, and improve stability.

Through total variation (TV) denoising and convex optimization, the reconstructed light-field image achieves an impressive peak signal-to-noise ratio (PSNR) and structural similarity index (SSIM). Experimental data show a 5.95% PSNR improvement and 1.77% SSIM enhancement compared to traditional friction-oriented LC-MLA.

This study pioneers LC-MLA application in super-resolution light-field image reconstructions, leveraging AZO’s unique properties to optimize liquid crystal alignment and overcome the limitations of traditional imaging techniques. The findings pave new avenues for light-field cameras, displays, and computational imaging, offering significant theoretical insights and practical applications.