Enhancing the Detection Sensitivity of PbSe Thin Film TTE Photodetector by Adding Light-Trapping Coatings

The thin-film transverse thermoelectric (TTE) photodetectors enhance the sensitivity of PbSe thin-film detectors by utilizing graphite coatings with light-trapping structures. The TTE effect generates a surface voltage from light-induced temperature differences, enabling self-powered ultrabroadband photodetection without external power sources.

Graphite coatings significantly improve light absorption and minimize reflection, boosting photothermal conversion efficiency and detection sensitivity. The optimized coated films show superior performance across a broad spectral range, offering advancements for photodetectors and thermal sensor technologies.

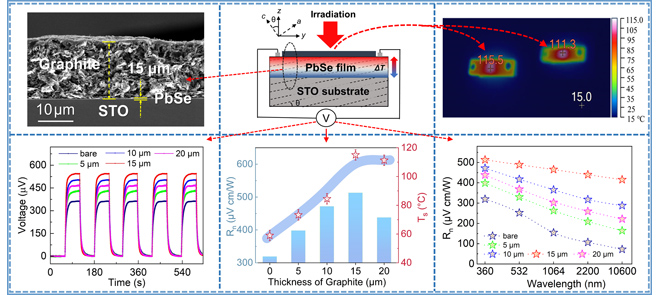

A c-axis inclined PbSe thin film (~225 nm thick) was grown on a 10° miscut SrTiO 3 (STO) single-crystal substrate using pulsed laser deposition. Graphite coatings with varying thicknesses of 5,10, 15, and 20 µm were applied by spraying GRAPHIT 33 through a rectangular metal mask.

The 15-µm-thick graphite-coated PbSe film, with a coarse surface and randomly stacked graphite flakes, forms a light-trapping structure that boosts light absorption and photothermal conversion, enhancing detection sensitivity.

The film's surface morphology and microstructure were analyzed using scanning electronmicroscopy, and optical absorption spectra were measured with a U-4100 spectrophotometer.

Transverse thermoelectric voltage signals were recorded with a Keithley source meter under continuous-wave laser irradiation, confirming positive ohmic contact through linear current-voltage characteristics with indium electrodes on the graphite-coated sample.

The interface between the 15-µm graphite coatings and the 225-nm PbSe film aids efficient heat transfer from absorbed light to the surface of the PbSe film, improving the photothermal process, while the thickness of the film ensures good structure and performance.

TTE performance was tested by measuring voltage signals from bare and graphite-coated PbSe films under different laser lights. The peak voltage increased significantly with the graphite coatings, reaching around 545 µV for the 15-µm-thick coatings, which is 160% higher than the 340 µV from the bare film. This improvement is due to the light-trapping structure that increases light absorption and detection sensitivity.

The graphite coating significantly improves photodetector performance by increasing light absorption, especially in the 400–2500 nm range, and enhancing noise resistance across all wavelengths. The voltage response also showed a strong relationship with laser power density across different wavelengths, confirming the practical use of these photodetectors.

The coatings trap more light, raising the surface temperature and increasing the temperature difference between the top and bottom of the film. With an optimal thickness of 15 µm, the coating achieves the highest light absorption and a surface temperature of 115.5°C, boosting noise resistance and peak voltage.

Beyond this thickness, heat dissipation reduces thermal transfer efficiency, lowering the temperature difference and peak voltage. These results emphasize the importance of optimizing graphite thickness, with the 15-µm coating outperforming other light-absorbing layers.

Overall, light-trapping graphite coatings significantly enhance the TTE performance of PbSe thin-film photodetectors, improving sensitivity across a broad range of wavelengths. The 15-µm graphite-coated film achieved a noise resistance of 415 µV cm/W under 10.6-µm laser irradiation, nearly five times that of the bare film, highlighting the potential for advancing photodetector sensitivity and thermoelectric thermal sensor applications.