E-Nose System Based on Fourier Series for Gases Identification and Concentration Estimation From Food Spoilage

An Electronic Nose (EN) is a device that imitates the olfactory sense of mammals. The EN model has two main components: a gas sensor array and a pattern recognition algorithm. The gas sensor array helps identify and estimate the concentration of single and binary mixed gases, while pattern recognition helps to overcome the cross-sensitivity of the gas sensors. With the advancement of machine learning algorithms and deep learning models, the accuracy and performance of EN systems have increased.

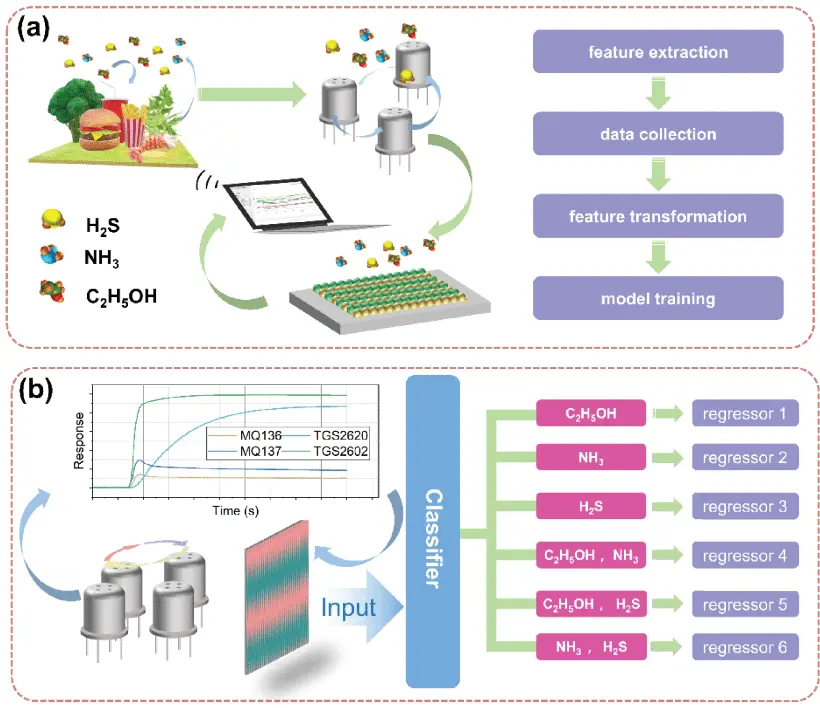

The proposed EN model comprises a gas sensor array, a data acquisition board, and a wireless transceiver module. The gas sensor array, with the help of machine learning algorithms, can detect gases emitted from spoiled food. The array includes four metal-oxide-semiconductor (MOS) gas sensors, namely TGS2602, TGS2620, MQ136, and MQ137. These sensors are sensitive to C2H5OH (ethanol), which is released from rotten fruits, and H2S (hydrogen sulphide) and NH3 (ammonia), which are emitted from high-protein foods like beef, egg, fish, meat, etc. when contaminated by microorganisms. The sensors can also detect the binary mixture of all three gases.

Data acquisition circuit boards were utilized to gather data from an array of gas sensors. A new method based on the Fourier series was introduced to enhance data processing. The collected data was then converted into colored images using the Fourier series. This approach effectively harnessed data while minimizing interference.

These images were analyzed using a convolutional neural network (CNN) model with a dropout algorithm. The analysis aimed to identify the presence of single and binary mixtures of emitted gases and estimate their concentration based on the sensor response. A mathematical model was developed for precise gas concentration prediction based on the collected data and sensing principles. Combining the CNN model and dropout technique increased the classification accuracy rate to 91.9%.

An experiment was conducted to simulate realistic food spoilage. This was done by creating a mixture of 1000-ppm H2S standard gas, 5000-ppm NH3 standard gas, and pure ethanol in a sealed chamber. The gas ratios were controlled by a flowmeter and injected into the chamber, where they were allowed to mix thoroughly. Pure ethanol was injected into the chamber using a micro syringe to ensure accurate results. Real-time sensor resistance values were transmitted to a computer via Bluetooth for monitoring.

Sample imbalance in the training set and experimental setup can significantly affect the performance of a classifier. The Synthetic Minority Oversampling Technique (SMOTE) was used to address this issue. SMOTE helps to reduce the negative impact of sample imbalance on classification tasks, minimizes the fluctuations that affect accuracy, and improves the prediction and overall performance of classification models. With the use of SMOTE, the accuracy rate was improved to 96.67%.

Electronic gas sensors are frequently employed for monitoring air pollution monitoring and detecting gases in industrial environments. The proposed EN system is portable, simple, and has the advantage of achieving high accuracy in checking freshness and detecting gases that result from food spoilage. It is cost-effective and can be used in the home.