Design, Development and Characterization of Textile Stitch-Based Piezoresistive Sensors for Wearable Monitoring

E-textiles have been an area of interest for many researchers and commercial applications since the last decade. The miniaturization and integration of electronics into textiles have opened the doors to smart clothing with embedded sensors, bringing functionality and aesthetics to our daily life in the fields of sports, healthcare, fashion, and defence.

Integration of electronics directly into a textile structure has enabled the development of textile-based sensors. These sensors are flexible, stretchable, and comfortable to the wearer. There is a wide range of techniques to fabricate textile-based sensors. Machine-stitching is a novel and most scalable method to develop stitch-based piezoresistive sensors. Stitching can be used to create free-form sensor designs, unlike other methods where the sensor size, shape and design are difficult to achieve for E-textiles.

E-Textiles works on the concept of external stimulus. The textile-based sensors and electrodes are made of flexible conductive threads, fibres, or fabric that can be integrated into upholstery, garments, shoes and mats. It can be useful in the health, sports, defence, and the automotive industry since vital signs, like respiration rate and electrocardiogram signals of the human body can be measured with the embedded sensors.

The multi-layer sensors are designed and developed by using stainless steel thread stitched on a piece of fabric together with a conductive sheet and a semi-rigid material. These sensors work on the principle of Force Sensing Resistor (FSR), where the resistance of the thread decreases as the applied pressure on the sensor increases. When the contact area between the multi-filament thread and the conductive sheet increases, the shape of the thread changes from circular to elliptical, resulting in the resistance drop across the terminals of the thread.

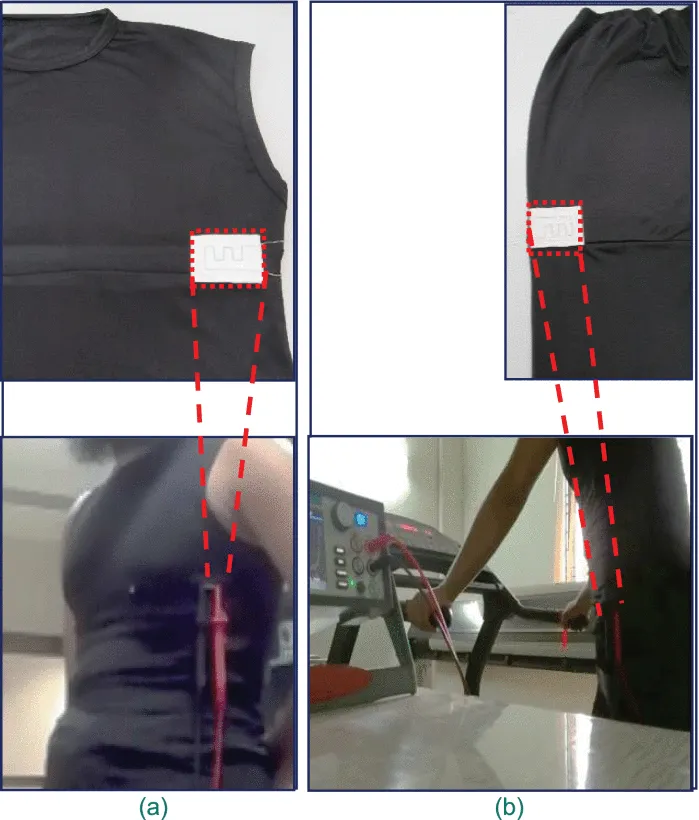

The researchers evaluated the performance of sensors made from different conductive thread lengths. They found that the sensors with a higher conductive thread length are more sensitive and have a better pressure sensing range. The developed sensors showed good fatigue resistance, at least in 3000 cycles. Moreover, the developed sensors were embedded into the garment to monitor the wearer's vital signs and muscle activities successfully.

This research presents an innovative fabrication technique to develop textile-based sensors which can easily be embedded into a garment for an extended period without any signs of deterioration. This knowledge suggests the future direction of smart textiles, which could soon transform the clothing industry and have a massive economic impact.

E-textiles are considered the future of Internet-of-Things (IoT), the main component of the Fourth Industrial Revolution (4IR), because of their seamless integration with fibre materials and flexible connectivity. The ever-growing advancements in wearable technology will have a substantial impact on the quality of human life.