CMOS-Based Tactile Force Sensor: A Review

Humans interact through their sensing organs, like touch, smell, taste, hearing, and seeing. In the development of modern technologies, significant attention has been given to the design and fabrication of sensors that can imitate the capabilities of human sensing organs.

The researchers are working to incorporate sensing into the machines/robots as closely as possible to better their functions in numerous applications. Successful examples of applications for these sensors may include the optical sensors (vision) in self-driving cars or microphones (hearing) incorporated into virtual assistance systems (e.g., Amazon Alexa), thereby bringing “life” (intelligence) into lifeless technological systems.

Incorporating sensors that can provide tactile information for machines is a crucial step in the advancement of human-machine interfaces and in facilitating machine-to-environment or machine-to-machine interactions. Due to the high demand for tactile sensors, researchers and companies are developing tactile sensors using different sensing mechanisms.

One of the important characteristics of modern applications of tactile sensors is their “compactness.” Researchers are excited about the miniaturized, “chip-scale” tactile sensors the micro-electro-mechanical systems (MEMS) approach enables. Hence, the MEMS approach has become the frontrunner for developing modern tactile sensors.

One subcategory of the MEMS approach for fabricating tactile force sensors is through the use of the Complementary-Metal-Oxide-Semiconductor (CMOS) platform. The CMOS platform is a standard fabrication platform traditionally used to produce integrated circuits (IC). Moreover, the CMOS platform is also well-suited for fabricating MEMS tactile force sensors because of its mature and stable process, potential System-on-Chip (SoC) solution with IC, and the multitude of available functional materials provided in the platform.

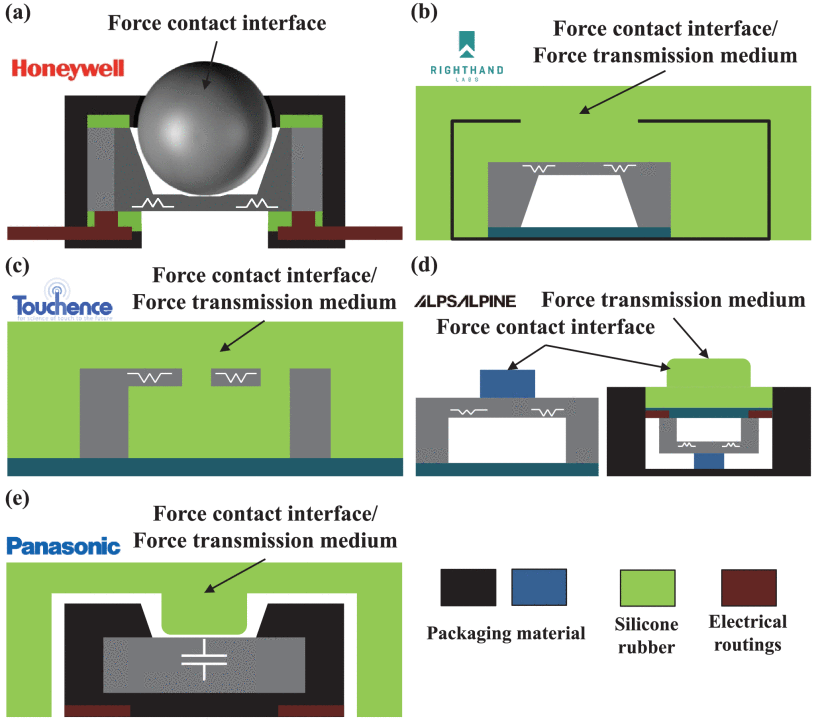

Several design concerns arise when fabricating CMOS-based tactile force sensors, which include those related to the sensing structure of the sensor, the implementation of force contact interface/mediums, and methods of post-CMOS fabrication.

Due to the distinct working principles of different sensing mechanisms, a wide variety of sensing structures can be utilized for tactile force sensing, which includes cantilevers, bridges, or membranes. Each has advantages and disadvantages. They are fabricated through different post-CMOS fabrication steps (either by etching excess material or bonding with additional chips).

Further enhanced force sensing capabilities (e.g., multi-axes force sensing, force mapping, etc.) can be achieved by clever structural designs and spatial arrangements. Additionally, for practical usage of miniaturized force sensing chips, polymer fillers are generally integrated as a force transmission medium and the protection for microstructures. Also, the contact interface is a crucial design aspect and can be realized in various post-CMOS fabrication methods.

The CMOS platform enables considerable design flexibility for tactile force sensing and is a promising technology for realizing tactile sensors. In the future, the powerful capabilities of the CMOS platform can be extended to monolithically integrate tactile sensors with other CMOS-based sensors. Such development will reshape how we, as humans, interact with technology and the way technology interacts with each other.