Chipless RFID Sensors for Wearable Applications: A Review

Radio Frequency Identification (RFID) technology has long been used for remote asset management, authentication, and tracking applications. Researchers have tried to explore the electromagnetic properties of RFID tag antennas to use them as a sensor. The energy harvested from radio waves received by the antenna further help to develop a passive, remote sensor module.

These sensors can be integrated seamlessly into existing, ubiquitous RFID systems, enabling the capture and gathering of huge amounts of information in fields such as smart homes, healthcare, the internet of things (IoT), surveillance, and banking.

A traditional RFID tag has an antenna transceiver and an integrated circuit (or chip) that stores the tag's identification and other information.

RFID sensors are categorized as active if they have a battery onboard or passive otherwise. Active sensors can transmit over an expansive range of frequencies. They can achieve high data transmission over long distances. However, these sensor systems are complex, have a high maintenance, and have a shorter lifespan.

Passive sensors can be powered externally, allowing for a simplistic onboard circuit. The reader/antenna probes the tag by sending radio waves. The energy received through the antenna can activate the chip. The information on the chip modulates the energy, which is reflected toward the antenna/reader. Passive tags are more robust and energy-efficient but have comparatively limited data storage and transmission range.

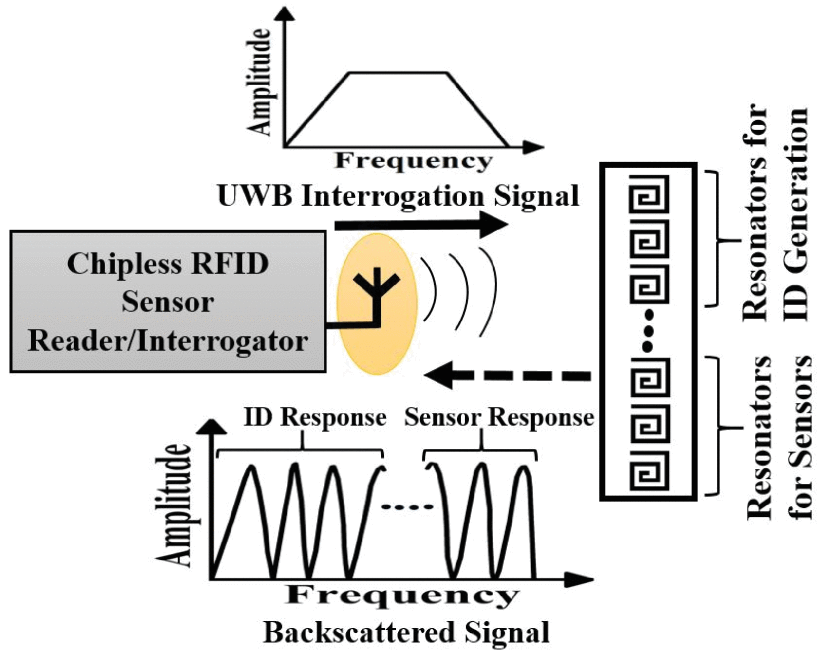

Certain qualities of antennae, like, impedance or radar-cross-section (RCS), depend on the change in their environmental parameters. Recently introduced Chipless RFID sensor tags work by measuring these changes and modulating the backscatter signal accordingly. The transceivers in chipless RFID typically work on principles of time-domain reflectometry (TDR), frequency modulation (FM), or phase-encoding. In TDR-based architecture, interrogating and backscatter signals get transmitted in pulse form. The FM-based system decodes information from RFID tags utilizing resonant circuits. Passive RFID sensors usually employ high-frequency (13.56 MHz) or ultrahigh-frequency (860-960MHz) antennas and can have a read range of more than one meter.

Chipless RFID tags could be printed on low-cost paper, plastic, wood, and fabric substrates using conductive ink. Another method is knitting conductive yarns to design flexible and stretchable RFID sensors for wearable devices. Many Functional materials like PVA, Phenanthrene, Kapton, graphene, metallic oxide, or single-walled carbon nanotubes (SWCNT) have been studied for their low-frequency uses. These materials are sensitive to environmental variations such as temperature, pressure, humidity, strain, and electrical parameters.

The chipless tags are flexible, stable, affordable, durable, and can be mass-produced. These RFID sensors are suitable for public places like hospitals, airports, smart homes, or personalized monitoring.

Chipless RFID tags still face challenges concerning the thickness and conductivity of textile resolution and viscosity of the conductive ink. A human body's high permittivity leads to decreased RCS and detuning of nearby antennas. An array of modulated Frequency Selective Surface (FSSs) based dipoles embedded in a varactor diode at tag antenna can improve the RCS value and frequency range (2.45 GHz).

The chipless RFID tag shows great potential for mass production as a flexible, energy-efficient, lightweight sensor in wearable devices and remote security systems.