A Single-Chip AlScN PMUTs-on-CMOS Hydrophone

Ultrasound transducers used in biomedical applications for high-resolution images of organs, neuromodulation, etc., require a previous characterization to guarantee the safety of medical procedures, avoid harm to health, and are necessary to meet the specifications provided by standards and regulatory bodies. Hydrophones are widely used in this context because they convert acoustic pressure into electrical signals, allowing extraction parameters such as instantaneous acoustic pressure, acoustic intensity, peak compressional (P+) and peak rarefactional (P−) pressures, etc.

Designing high-performance hydrophones involves some constraints. The most critical points are the small size, high sensitivity (re: 1V/Pa) with a broad range frequency, low noise, and cost-effectiveness. All these parameters are essential because hydrophones with small aperture sizes ensure the correct estimation of the peak pressure and the beamwidth and allow the measurement of acoustic pressures close to the transducer under test. The high sensitivity with a flat frequency response guarantees a precise acoustic pressure estimation at several frequencies, and the low noise values (associated mainly with the amplification) allow the measurements of low-pressure levels. Finally, the miniaturization of the hydrophone system (including the amplification block) is pursued to have a compact device suitable to characterize any ultrasound transducer regardless of its size.

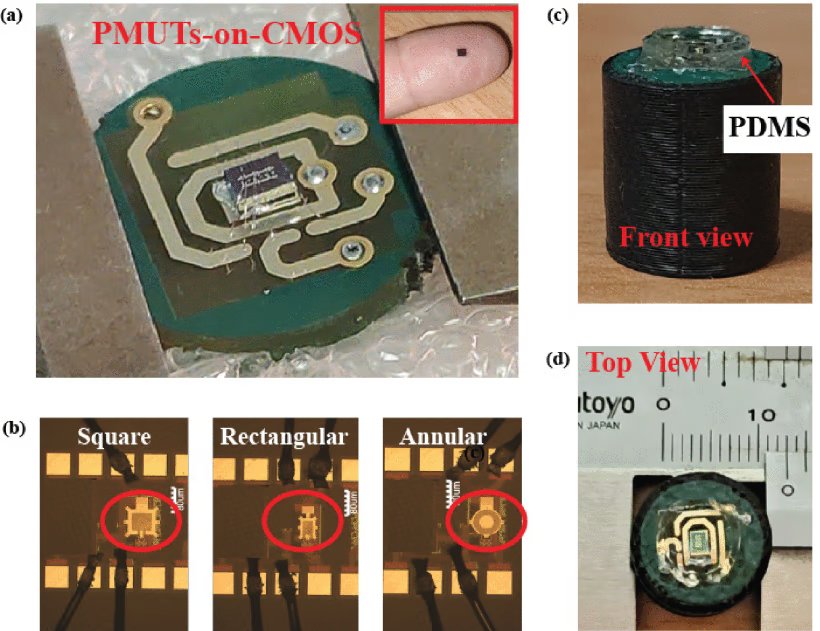

This paper presents a single-chip based on a PMUT integrated monolithically on CMOS circuitry (PMUTs- on-CMOS) with great potential as a hydrophone. The solution provides a compact device that includes the sensor element and the amplifier, reducing the total area (1.9 × 1.5 mm, including both the circuit and the PMUT). In addition, the monolithic integration improves the signal-to-noise ratio and, consequently, the system sensitivity by decreasing the parasitic capacitances and avoiding bonding techniques.

The hydrophone system is based on three different transducer geometries (square, rectangular, and annular) with small active areas (maximum size 80 μm), and each one is directly connected to a CMOS LNA amplifier. The devices have been fabricated using the commercial MEMS-on-CMOS platform from Silterra. They consist of a 0.6 μm AlScN piezoelectric layer between two Al electrodes (0.15 μm bottom electrode and 0.2 μm top electrode), and, finally, a 1.5 μm Si3N4 is deposited on the top, acting as a passive layer.

A preliminary prototype was characterized in water in a frequency range from 1 MHz to 10 MHz, and the main results show that it is equally competitive compared to the commercial ones. The mean sensitivity achieved is -236 dB (re: 1 V/μPa) instead of −266 dB (re: 1 V/μPa) for a commercial hydrophone (including the preamplifier) of almost the same dimensions, showing an improvement of 30 dB.

Another benefit a single-chip AlScN PMUTs-on-CMOS hydrophone is the achievable minimum measurable pressure level since pressure levels higher than 200 Pa could be detected by the PMUTs-on-CMOS systems, which is not possible by some commercial hydrophones.

All results offer an approach where a single chip can have several independent reading points with the capacity to position closer to the transducer under test with a high sensitivity and a low noise validating its potential for high-frequency ultrasound applications.