A Novel Differential Capacitive Humidity Sensor on SIW Re-Entrant Cavity Microwave Resonators With PEDOT:PSS Film

The humidity sensors have broad applications in pharmaceutical manufacturing, modern agriculture and industries, crop production and food storage, structural health monitoring, environment monitoring, semiconductor, textiles, biomedical, and microelectronics. The demand for humidity sensors has led the researchers to work to advance the humidity sensing technology to sense even minor variations in environmental humidity at a given temperature and condition.

There are mainly two ways to improve the humidity sensing functioning:

- Using advanced humidity sensitive (HS) materials.

- Designing a microwave resonator.

The HS materials method is not universal, rely on a complicated synthesis process and materials are usually loaded on the entire surface of the resonator. Also, the HS materials are scarce and susceptible to environmental damage, like dust and stains.

The SIW technology was found suitable for enhancing the humidity sensitivity and resolution for designing the microwave resonator. The introduction of the air-filling technology improved the Q-factor, and metal grid holes (METGH) improved the flowability of the humid air in the sensor, enhancing the sensitivity in the SIW resonator. The folding technology integrated with SIW technology made easy integration with other planar circuits possible, resulting in miniaturization in design.

However, both the methods didn’t consider the effect of temperature on the humidity sensors. The environmental temperature has an impact on resistive humidity sensors. The conductivity or resistance of the HS film changes with temperature.

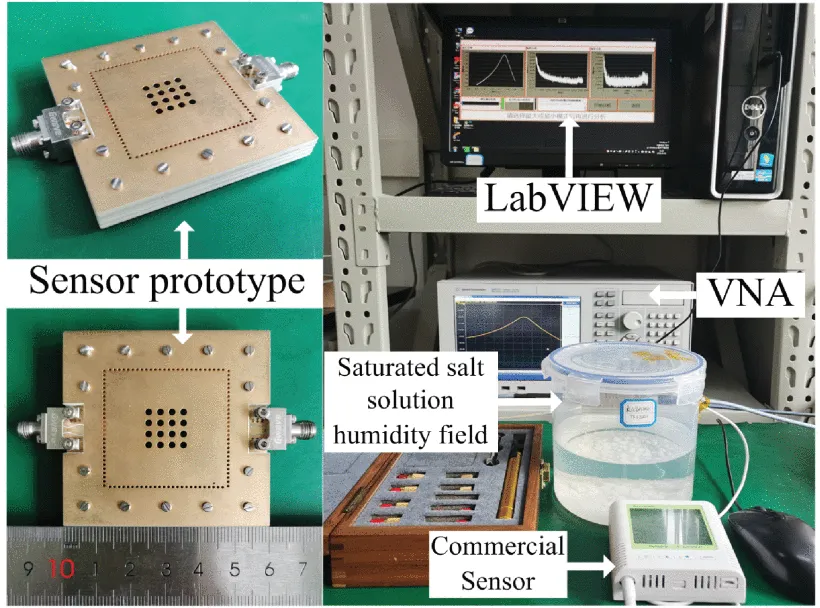

The researchers proposed novel differential microfluidic sensors to overcome the challenges in humidity sensing technology. Differential sensors have two resonators, referencing and sensing resonators. A differential humidity sensor based on SIW RECR was designed where the two RECRs are longitudinally integrated and covered with PEDOT: PSS (poly(3,4-ethylene dioxythiophene)-poly(styrene sulfonate)) to reduce the size, increase humidity sensitivity and avoid interference from environmental temperature and conditions.

The two RECRs stacked longitudinally, one with a larger capacitance post area is used as a sensing cavity and the smaller one as the referencing cavity. The SIW RECRs consist of three dielectric substrates, Rogers RO4350B with εr = 3.48 and tanδ = 0.0037. Substrate 1, 3, 4 and 6 (S1, S3, S4 and S6) is 1.524 mm thick, and substrate 2 and 5 (S2 and S5) is 0.508 mm thick. The upper and lower surfaces of the substrate are covered with a 35 um metal layer. The metal wall that separates the two RECRs suppresses the electromagnetic coupling between them. Square grooves, the same in size as the capacitance post of each RECR, are etched in S3 and S4 as humidity sensing areas. The HS PEDOT: PSS film is deposited in the sensing area to enhance the humidity sensing performance. The tapered coplanar waveguide-to-stripline-to-SIW transition transformer is etched in the stacked metal layer to feed microwave signals to the two SIW RECRs. The two substrates, S2 and S5, are kept partially hollowed from the top metal layer to the bottom metal layer to form an air-filled dielectric substrate.

The differential humidity sensor devised and made using air-filling, METGH, and HS material improved humidity sensing performance, reaction time and sensitivity. It also avoids cross-sensitivity phenomena from environmental temperature. Air-filling, METGH, HS material, and differential arrangement increased the sensing performance of the microwave humidity sensor performance.