A Novel Anti-Relaxation Material Applied in Miniaturized Atomic Spin Gyroscope

With the widespread inclusion of Unmanned Aerial Vehicles (UAVs) in both military and civilian fields, the need for microminiaturization has become increasingly crucial.

Miniaturized atomic spin gyroscopes (NMRGs) are tiny devices that measure rotation using the spins of atoms inside a small vapor cell, making them essential for navigation in environments where GPS signals are unavailable.

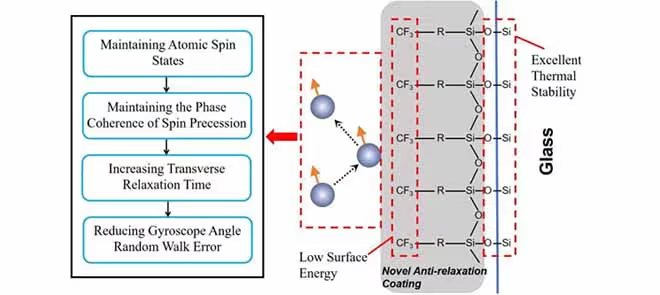

However, reducing the size of the alkali vapor cell leads to frequent atomic collisions with the inner glass surface, causing significant spin relaxation. This reduces the transverse relaxation time, lowering the overall accuracy of the gyroscope.

Commonly, anti-relaxation coatings are used to minimize wall-induced relaxation by isolating polarized atoms from direct contact with the glass walls. Traditional coatings, such as paraffin or RbH, have been used in the past; however, they fail at operating temperatures of nearly 110°C due to weak bonding.

This research presents a novel anti-relaxation coating based on perfluorododecyltrichlorosilane (PDTS), featuring fluorinated —CF₃ terminal groups known for extremely low surface energy and excellent hydrophobic properties.

The PDTS coating is synthesized through a carefully controlled chemical reaction, where a platinum catalyst ensures smooth processing, operating in an inert and oxygen-free environment.

This coating forms strong covalent bonds with the hydroxylated glass via a reactive trichlorosilyl (–SiCl₃) group, providing excellent adhesion and thermal stability. Its long carbon chains also separate the polarized atoms from magnetic disturbances on the glass, further reducing spin decoherence.

After synthesis, the coating is applied to tiny vapor cells using a precise solution-based method and then cured under controlled conditions to ensure stability. Safety precautions are taken throughout to protect researchers from chemical hazards, without affecting the quality or performance of the coating.

Fourier transform infrared (FTIR) spectroscopy verified the formation of the expected chemical bonds. Si–O–Si linkages and the characteristic C–F vibrations of the —CF₃ groups were clearly observed, showing that the PDTS coating was successfully synthesized with the correct chemical structure.

Contact angle measurements revealed that the coating significantly reduces surface energy to 18.37 mN/m at the optimal concentration, which is substantially lower than that of Octadecyltrichlorosilane (OTS) coatings, thereby improving its anti-relaxation performance.

Atomic force microscopy showed that the coating is smooth and even, which helps reduce spin relaxation hotspots. Measurements of transverse relaxation time showed clear improvements. PDTS-coated cells reached an average of 28.8 seconds, outperforming OTS (21.7 s) and RbH (18.4 s) in both stability and duration. This improvement is directly linked to fewer disturbances of atomic spins at the cell surface, as predicted by theory.

The new PDTS coating, featuring strong covalent bonds and low-energy fluorinated groups, overcomes the previous limitations of miniaturized NMRG performance. Its thermal stability and excellent spin coherence make it promising for use in compact atomic gyroscopes for UAVs and other precision navigation devices, improving both sensitivity and reliability.

This study demonstrates that PDTS coatings impr0ves the accuracy of miniaturized NMRGs by extending transverse spin relaxation and reducing angle random walk errors, providing a scalable pathway for the next-generation of navigation sensors.