Highly Sensitive Flexible Sensor Over a Wide Linear-Range Based on Carbon Nanotube Toward Physiological Monitoring

Capacitive pressure sensors (CPSs) are widely used in wearable electronics and physiological monitoring due to their low power consumption and simple construction. They operate by deforming a dielectric layer between electrodes, which alters the capacitance in response to the applied pressure. However, traditional CPSs often struggle to achieve high sensitivity and a broad, linear detection range, especially under dynamic pressures.

Researchers integrated conductive nanomaterials such as graphene, carbon nanotubes (CNTs), MXene, and metal nanoparticles into the polymer matrices to improve sensitivity. These fillers helped form a percolation network that enhances the dielectric constant up to a threshold, but beyond this point, the formation of conductive paths reduces dielectric performance. This happens due to a lack of precise control over the filler concentration and dispersion amount.

The MXene-based composites enhance mechanical properties but experience leakage currents, which require additional Polyethylene Glycol pre-treatment and TPU blending to control this. Because of these factors, achieving both high sensitivity and broad-range linearity remains a key challenge.

This study enhances traditional capacitive pressure sensors by developing a composite dielectric layer made from polyvinylidene fluoride (PVDF) and thermoplastic polyurethane (TPU) based on a Carbon Nanotube design. The TPU’s elasticity improves stress distribution, boosting sensitivity to low pressures, while PVDF’s high polarity enhances dielectric strength and overall sensor performance. To further optimize sensitivity, multi-walled carbon nanotubes (MWCNTs) are added as microelectrodes, increasing capacitance and improving pressure response.

Flexible electrodes made of gold, copper, and polyethylene terephthalate were used to fabricate the multi-walled layer, with the layers secured using laser-cut double-sided tape. A 1 N load was applied during assembly to eliminate residual stress. Sensor performance was evaluated through compressive stress-strain tests and capacitance measurements using an LCR meter connected to a LabVIEW program.

Dopamine was used to improve MWCNT dispersion and prevent a decline in MWCNT sensor performance under excessive pressure. The resulting sensor detects light pressures as low as 100 Pa and offers high sensitivity (3.34 kPa⁻¹), operating over a broad range of 2–50 kPa with quick response time (156/153 ms).

In the material screening phase, PVDF outperformed the other combinations with a dielectric constant of 7.56 at 1 kHz and sensitivity of 0.87 kPa⁻¹. Blending PVDF with TPU expanded the detection range, incorporating 3% of the MWCNT weight to further enhance sensitivity through micro-capacitor formation. The dopamine coating further optimized the dispersion of MWCNTs by incorporating another 10% of the total weight of the PDA layer.

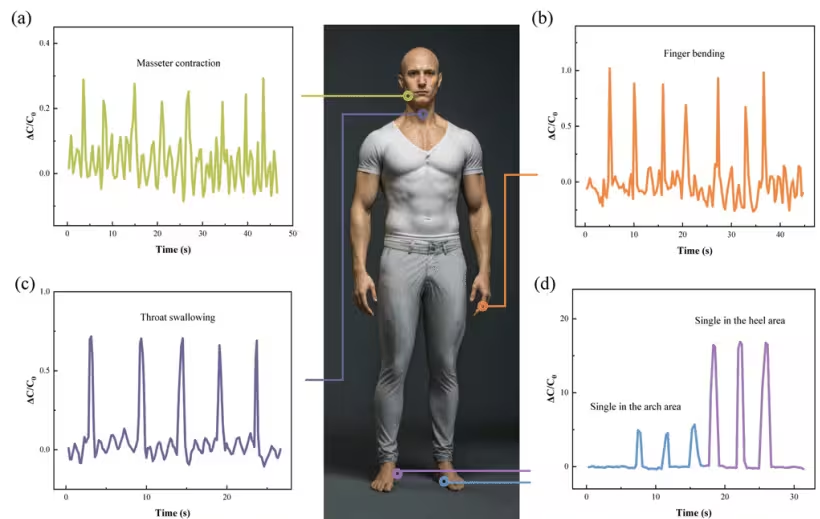

Long-term durability tests confirmed the reliability of this carbon nanotube-based sensor. It maintained stable capacitance over 2000 cycles, with only minor fluctuations due to structural compression and stress redistribution. These results highlight its potential for real-time physiological monitoring.

The sensor is effective at detecting low-pressure signals like muscle movements, joint flexion, swallowing activity, and plantar pressure distribution. With high sensitivity, broad detection range, quick response, and excellent stability, it is well-suited for wearable health monitoring and robotic tactile sensing. This technology shows great promise for advancements in personalized healthcare and human-robot interaction applications.