Fabrication and Characterization of P3HT/MoS₂ Thin-Film Based Ammonia Sensor Operated at Room Temperature

Ammonia, a colorless toxic gas emitted from agricultural activities, livestock, and vehicles, poses significant threats to flora and fauna when exceeding limits. Exposure can cause severe consequences like blindness, death, lung damage, coma, collapse, and seizures. The advancement of efficient ammonia gas sensors is critical to safeguard human health and the environment.

Several methods have been described for sensing ammonia, including metal oxide (MO) sensors, conducting polymer (CP) sensors, tunable diode laser spectroscopy (TDLS), electrochemical sensors, and surface acoustic wave sensors. Recently, composite of conducting polymer and two-dimensional (CP/2D) materials have been a topic of interest.

Although CP-based sensors exhibit good sensitivity and room temperature operation, they suffer from a low response, poor stability, or less lifetime. Doping or fabricating nanocomposites like poly(3-hexylthiophene)/ molybdenum disulfide (P3HT/MoS2) offers a synergistic blend of material advantages, delivering stability, sensitivity, and stability of CP-based sensors. The enhanced current densities and improved charge transport properties make PTh derivatives and composites like P3HT/MoS2 ideal for fabricating OFETs.

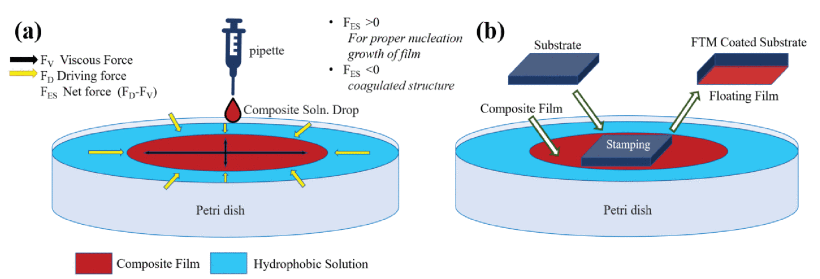

Various methods, like dip casting, spin casting, vacuum deposition, Langmuir-Blodgett deposition, layer-by-layer self-assembly, and the floating film transfer method (FTM), are used for depositing thin films of conducting polymers (CPs). FTM, a solution-processable technique, involves obtaining a thin floating polymer film over the liquid surface, forming a self-assembled monolayer (SAM) through the polymer sol-gel formation.

The paper outlines the development and characteristics of a highly efficient ammonia gas sensor utilizing a poly(3-hexylthiophene)/ molybdenum disulfide (P3HT/MoS2) nanocomposite in an organic field-effect transistor (OFET) architecture.

The stability of the conjugated polymer composite, P3HT/MoS2, is enhanced by MoS2, resulting in superior sensing response, mobility, and a reduced detection limit. The MoS2 in the P3HT polymer increases the surface-to-volume ratio (S/V) of the sensing film, expanding its sensing area. The X-ray diffraction (XRD) and absorption spectra of the synthesized film show that the P3HT crystallization and conjugation via MoS2 material in P3HT/MoS2 nanocomposites have been enhanced. The atomic force microscopy (AFM) image of the synthesized film also shows superior morphology of P3HT/MoS2 composite compared to pristine P3HT film in terms of ammonia gas sensing.

A bottom gate top contact (BGTC) organic field-effect transistor (OFET) architecture has been fabricated on a highly p-doped silicon wafer with P3HT/MoS2 serving as the active channel material deposited through the FTM technique.

To explore gas sensing, the OFET sensor is exposed to varying concentrations of ammonia, which affects device parameters. The gas sensing response is attributed to a redox reaction, where reducing gases, like ammonia, extract positive charges from the surface, reducing drain current (IDS). The sensing response of the OFET sensor exhibited decreasing trends with ammonia concentration and increasing trends from 0 to 100 ppm, indicating high selectivity. It shows a threshold voltage of 3.78 V (in the air) and changes to 10.71 V after 100 ppm ammonia gas exposure. The sensor's detection limit, another crucial performance metric, was determined to be 904 ppb.

The fabricated OFET has various advantages, such as high efficiency, enhanced performance, better sensitivity, and a non-invasive and low-concentration ammonia gas sensor.