Investigation on Substrate Material for a Sensitive Flexible Piezoresistive Pressure Sensor

Flexible piezoresistive pressure sensors (FPPS) are emerging as vital components for next-generation wearable devices, soft robotics, healthcare monitoring, and human–machine interfaces.

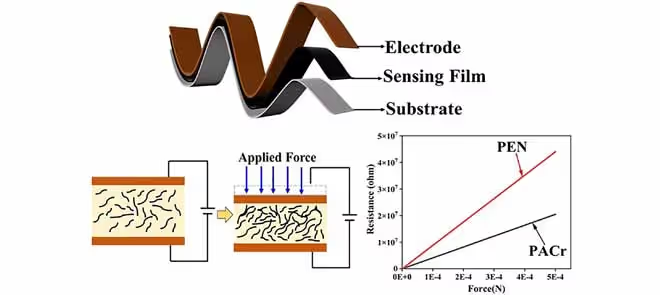

They operate on the piezoresistive effect, converting mechanical pressure into measurable electrical resistance changes. FPPS are highly attractive due to their high sensitivity, fast response, excellent flexibility, and low-cost fabrication, making them suitable for diverse applications.

However, the substrate material plays a critical role in determining sensor performance, influencing mechanical stability, thermal durability, and user comfort. Traditional substrates like silicon wafers and metal foils lack flexibility, while polymer-based substrates provide better adaptability but vary widely in their mechanical and thermal properties. Selecting the most suitable substrate remains a key challenge for optimizing FPPS design.

This research presents a structured approach to identify the optimal substrate for FPPS by focusing on key material attributes, including the coefficient of thermal expansion (CTE), Young’s modulus, thermal conductivity, glass transition temperature, and water absorption. These parameters directly affect sensor durability, stability, and compatibility with active sensing layers.

Two multi-criteria decision-making (MCMD) methods are used to address this material selection trade-off: Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) and VlseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR). These methods rank candidate materials by comparing them to ideal and non-ideal benchmarks, providing a robust framework for selecting the most suitable substrate.

Several potential substrates commonly used in FPPS were evaluated, including polydimethylsiloxane, polyethylene terephthalate (PET), polyacrylate (PAcr), thermoplastic polyurethane (TPU), and polyethylene naphthalate (PEN).

Both TOPSIS and VIKOR consistently identified PEN as the most promising material. Its superior thermal stability, mechanical flexibility, and chemical resistance make it highly suitable for wearable and flexible electronic applications.

To validate these findings, simulation studies were conducted using COMSOL Multiphysics 6.0, modeling FPPS devices with graphene as the active layer on PEN and PAcr substrates.

Simulation results confirmed that PEN-based FPPS exhibited higher sensitivity, better linearity, and improved mechanical stability compared to PAcr. Specifically, PEN achieved a sensitivity of 0.032 kPa⁻¹ over a pressure range of 0 to 55.5 kPa, making it ideal for wearable applications such as finger bending, wrist movement, and soft robotic sensing.

Moreover, PEN demonstrated better tensile strength, lower elastic modulus, and superior charge transport properties, enhancing overall device performance. Challenges such as potential polymer degradation under UV exposure can be mitigated through protective coatings, thereby improving long-term reliability.

The investigation demonstrates that optimizing substrate materials can significantly enhance FPPS performance, enabling their seamless integration into wearable healthcare systems, soft robotics, and energy-harvesting devices.

While alternatives like PET and TPU remain viable for specific use cases, PEN provides the best balance of mechanical, thermal, and electronic properties. Future research could explore surface treatments, hybrid composites, and interface engineering to further improve adhesion, stability, and multifunctionality.

By combining MCDM-based material ranking with simulation validation, this study provides a scalable methodology for substrate selection in flexible electronics. The findings confirm PEN as the optimal substrate for high-performance FPPS, paving the way for more reliable and sensitive wearable sensors in next-generation applications.